Overcoming Challenges to Maximize Efficiency- Changing Sub-Saharan Africa, one production line at a time.

Automation and its potential remain largely untapped, akin to a green field, as my mining colleagues would suggest. However, the implementation of automation in this region faces significant challenges due to the lack of reliable infrastructure. Despite this, hope is not lost, and the key lies in finding innovative solutions. The benefits of automation are immense for all stakeholders, including businesses, governments, and the population at large.

Sub-Saharan Africa is poised for significant growth in its industrial automation market in the upcoming years, driven by the increasing adoption of technology and the growing presence of robotics in the manufacturing sector. The implementation of Industry 4.0 in these countries is playing a crucial role in fuelling the demand for industrial automation. As a result, various industries, including automotive, agriculture, pharmaceutical, and food and beverage, along with small and medium-sized manufacturing units, are witnessing a surge in the application of automation technologies.

According to 6Wresearch’s projections, Nigeria, Ghana, Kenya, and Cameroon’s Industrial Automation Markets are expected to grow at varying CAGR rates of 6.0%, 4.5%, 4.6%, and 3.5% respectively during 2022-2028. In 2021, the food and beverage sector held the highest revenue share in these countries, reflecting its significant presence in their manufacturing sectors.

To diversify their economies and boost manufacturing sector output, these countries have implemented various government initiatives and schemes, such as Nigeria’s “100 for 100 Policy for Production and Productivity” and Ghana’s “One District One Factory.” These efforts are expected to drive future demand for industrial automation. Additionally, the establishment of special economic zones (SEZ) in Nigeria (38), Kenya (61), Ghana (4), and Cameroon (9) will further spur demand for industrial automation machinery. As these new infrastructure facilities for the manufacturing sector develop, they will promote increased production of finished goods to compete in the global market.

The impact of automation

By embracing a data-driven approach and harnessing ground-breaking technology, industries can surmount the challenges they encounter, elevating their operations to achieve greater profitability and sustainable economic growth. Predictive maintenance becomes feasible, empowering manufacturers to swiftly tackle system failures and minimize disruptions as they arise. Africa, with its youthful and rapidly expanding population, is experiencing a soaring demand for locally produced high-quality items, sustainable food- whether produced or manufactured, clean water, and readily available medications. Frequent recalls, production line downtime, and substandard products are luxuries manufacturers in sub-Saharan Africa cannot afford. Automation presents a solution to these issues, reducing downtime and addressing these manufacturers’ problems, thus enhancing the reliability of products for end consumers.

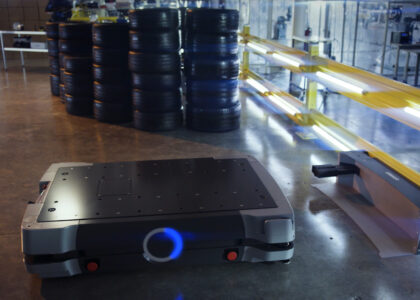

For 90 years, Omron has remained at the forefront of tackling the ever-evolving challenges in our society, harnessing the power of technological advancements. With a rich legacy of innovation, Omron has pioneered ground-breaking technologies that have had a positive impact on people’s lives worldwide. Significant contributions by the company span industrial automation, healthcare, automotive electronics, social systems, environmental solutions as well as mechanical components.

What are the key advantages?

Omron can bring numerous benefits to the production lines of manufacturers in Sub-Saharan Africa. Automation streamlines manufacturing processes, reducing manual intervention and human errors, which can be fatal in some cases. Automation leads to higher production efficiency and faster output rates, ultimately improving the overall productivity of production lines. These systems are consistent and precise, ensuring that products are manufactured to the same high standard every time. This results in improved product quality and reduced defects, leading to higher customer satisfaction and brand reputation.

Most think (and rightfully so) that the initial investment in automation may be significant. But the automation of manufacturing lines will lead to cost savings as it minimises material waste and optimises energy consumption, all of which contribute to improved profitability. Automated systems can be programmed and reconfigured to handle different products or manufacturing processes, cutting down significantly on equipment costs. This flexibility allows manufacturers to adapt to the ever-changing market demands and introduce new products to the market more efficiently. Automated systems can monitor equipment health, detect anomalies, and schedule maintenance before breakdowns occur. This minimises downtime and prevents costly production disruptions.

By embracing automation, manufacturers in Sub-Saharan Africa can compete more effectively in the global market. Increased efficiency and improved product quality can help them offer competitive prices and gain a stronger foothold in international markets.

While Industry 4.0 can create new job opportunities and provide solutions to various issues, there are concerns that automation and robots may replace traditional manual labour. Africa heavily depends on informal employment, and displaced workers might struggle to adapt to the changing job landscape. Embracing automation necessitates upskilling the workforce to manage and maintain automated systems. This presents an opportunity for workforce development and creates a more skilled labour pool, contributing to the region’s economic growth.

The Way Forward

Industrial automation can significantly benefit the production lines of manufacturers in Sub-Saharan Africa by enhancing efficiency, quality, safety, and adaptability. Embracing automation can lead to cost savings, data-driven decision-making, and increased competitiveness in the global market. Ultimately, it paves the way for sustainable growth and progress in the region’s manufacturing sector.

Written by Heleen Tshibumbu for Omron Automation