With a known history dating back to the Bronze Age, mining plays a critical part in human development as one of the oldest industries in the world economy. Mining pre-dates the first Industrial Revolution of the late 17th century, has transformed during the following two revolutions of the 19th and 20th centuries and, once again, the mining industry will have to transform and upskill for the 4th Industrial Revolution.

Mining, 4IR and the Artisan 4.0 initiative

Challenges faced by the mining industry today – such as increasing production costs, depressed commodity prices and the high cost of electricity – are forcing the mining sector to embrace further industrial transformation in the form of Industry 4.0 (4IR).

Developments associated with 4IR again bring training colleges and artisan training centres to the forefront, as workers now need to be upskilled to work alongside technology in the mining sector.

All modern technology creates a demand for skilled labour, and that is why the Colliery Training College (CTC) has risen to meet the opportunities of the occasion. CTC is the first training college to roll out an Artisan 4.0 initiative, which is a trademark pending registration.

When asked to explain what the term Artisan 4.0 means, Johan Venter responds: “Artisan 4.0 will still carry a toolbox similar to that of her father and grandfather; she will still know all about bearings, gearboxes and sequence starters because the basic principles of mechanics, electricity, forces and motion have not changed. The thing that will distinguish her from her father and grandfather is that she will communicate with her equipment via the Internet of Things. She will not only know that the pump in her plant has stopped, she will also know why.

“The pump, its motor and control systems will be connected to an industrial network. Artisan 4.0 will know everything about Internet protocols, IP addresses; how to set up networks, how to configure wireless devices. Her smartphone and her tablet computer will be alongside the set of sockets and screwdrivers in her toolbox,” says Venter, who is CTC’s managing director.

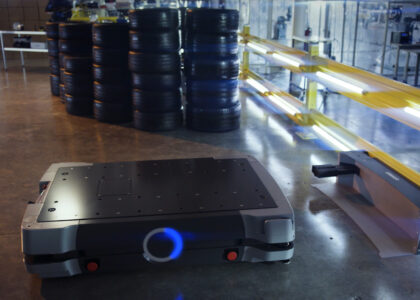

He believes that technological breakthroughs will benefit the mining sector as a whole and, by upskilling the workforce, socioeconomic conditions of workers will improve. Industry 4.0 and the current trend of coupling automation with data exchange in the industrial environment and technologies, involves the Industrial Internet of Things (IIoT) as well as cloud-based data processing systems. It leads to improved safety and security, efficiency and reduced production costs. Industry 4.0 also has a positive effect, Venter continues, on the maintenance load of the mine, because preventative maintenance programmes can be implemented.

“Communication between machines and the plant maintenance staff reduces downtime as well as preventing complete breakdowns. That, in turn, leads to higher productivity and, ultimately, higher profits,” he says.

“Industry 4.0 is a reality and it can’t be stopped. It is up to us as training facilities to bridge the gap and upskill our workforce, as well as equipping the new artisans of today with the skillset they will need to thrive in this revolution,” he says.

“We at CTC are working closely with our stakeholders and all interested parties to address the demands for highly trained artisans that are ready for the 4th Industrial Revolution,” Venter concludes.

The Colliery Training College was founded in 1965, initially to cater only for the mining sector but the college has since diversified and artisan skills training is now available for all industries that need artisans for the changing South African workplace.

CTC is accredited by the Mining Qualifications Authority (MQA) and the Quality Council for Trades and Occupations (QCTO).

Written by Heleen Tshibumbu on behalf of the Colliery Training College (2020)