Go Green for Gold!

New rules for sustainable packaging in the food industry

There can be no doubt in anyone’s mind that the amount of plastic packaging produced specifically by the food industry must urgently be reduced to avoid further damage to the planet. The advantages of plastics in the food sector should not be completely disregarded. What I am saying is that more efficient and resource-saving use is essential.

Plastic packaging is everywhere- from store shelves right through to everyday items in our households. It is widely employed in the packaging of products, from food wrappers to single-use water bottles. Its popularity as a packaging medium can be attributed to its versatility, low weight, hygiene, affordability, appealing look on the shelves and convenience. One should note that this convenience has a considerable cost to the environment. The Pew Trust estimated that approximately 11 million metric tons of plastic waste find their way to the ocean, causing unimaginable harm and damage to marine life. This waste also wreaks havoc on land and freshwater ecosystems.

The Playing Field

During the 1960s, the use of plastics became popular. Polyethylene, now one of the most widely used plastics globally, had its origins in 1898 and was reinvented in 1933. However, it was not until 1953 that the method for producing high-density polyethene was developed. This specific plastic, classified as No. 2 in recycling systems, is used mostly today in the production of plastic grocery bags. Recycling facilities face a significant issue with these plastic grocery bags. These bags tend to jam the processing equipment, causing work stoppages that bring the entire facility to a halt. Facilities set aside dedicated time for employees to clear the machinery of these bags. This process can also pose safety risks, as staff must navigate equipment and use sharp carpet knives to cut the bags free.

In 2023 environmental consciousness is on the rise, and businesses across the globe are evaluating their practices to align with sustainability goals. For the Food industry, this shift has been particularly impactful as packaging plays a vital role in the preservation and presentation of products. Take coffee capsules, for example: On the one hand, consumers want a quick and easy way to prepare a fresh cup of coffee in the morning. On the other hand, the popular disposable capsules represent a huge environmental burden. A more environmentally conscious consumer demands that coffee beans be grown more sustainably and fairly, that capsules be produced in a more environmentally friendly way, and their recycling becomes greener. New sustainable packaging and manufacturing approaches are the key.

But is it possible to strike a balance between adopting eco-friendly packaging methods and maintaining a healthy bottom line? The answer is YES and here’s how…

Playtime is Over

The environmental toll of conventional packaging cannot be overstated. Plastic pollution, overflowing landfills, and carbon emissions from production and disposal are just a few of the consequences. Recognizing this, consumers are increasingly demanding eco-friendly alternatives, and governments are imposing stricter regulations on packaging waste.

We should reduce plastic and rethink packaging. The food industry as well as other consumer goods companies are focussing more on the four “Rs” reduce, recycle, reuse and redesign. These industries are using new plastic compositions to enable easier recycling. Lately, there has been a rise in innovative designs such as recyclable bags, lids, or resealable bags (redesign and reuse) – less plastic and less waste in the final production stages. Exciting and fresh packaging are being developed.

Looking at one of the strategies for more sustainability in the food industry is reducing the amount of plastic, especially if it’s virgin. A key tactic to do it is shifting from rigid to flexible packaging Thinner walls, smaller sizes, narrower seams, and lighter weights are good ways to reduce the amount of virgin plastic used in the primary container.

Choose Your Best Player

A wide array of sustainable packaging options has been developed over the past 10 years. These innovative choices not only reduce the environmental impact but can enhance a brand’s reputation at the same time. Materials like PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoates) are derived from renewable resources and can be composted, significantly reducing the carbon footprint. Recyclable and biodegradable, paper-based packaging is a versatile choice for a variety of food and beverage products. It can be customized with eco-friendly inks and designs.

I find the edible packaging the most innovative out of all the available options. These options often made from ingredients like rice or seaweed, are out-of-the-box solution that eliminates waste and can surprise customers with a unique experience. These materials are endlessly recyclable, making them sustainable choices for the food and beverage industry. They are also less likely to leach harmful chemicals into products. Mycelium, the root structure of mushrooms, can be grown into various shapes to create sturdy, biodegradable packaging materials.

Sometimes, the most sustainable option is no packaging at all. Encourage customers to bring their containers for bulk purchases.

The 7 Best Plays on the Field

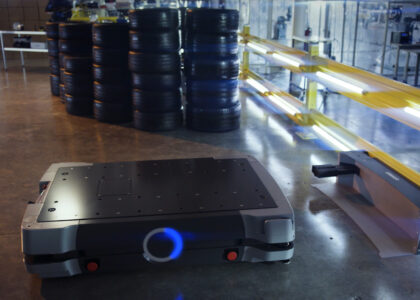

What is needed is future-proof manufacturing with automation and robotics technology that can work flexibly with different recyclable materials. The following 7 recommendations show you what to focus on:

- Sealing: Real-time monitoring– When material compositions change, companies must analyse whether machines such as vertical form fill seal machines (VFFS) can still maintain throughput and tension control without affecting the performance or quality of the final product. Only when you closely monitor and control the film, you have a product that meets specifications, bypasses wrinkles and stretching, and thus does not negatively impact downstream processes.

- Collecting data at the machine level and in real-time: Manufacturers need to ensure at all times that the packaging fulfils its purpose. Vertical form-fill-seal (VFFS) machines for example require many variables such as speed, pressure, synchronization, temperature and more to be precisely controlled and tested in real-time. To monitor multiple variables such as material thickness, contact time or temperatures, the manufacturer needs an automation solution that can collect all applicable data “at the edge” (at the machine level) via common communication methods. In addition, a facility for sharing and visualization is required. The development of embedding AI into a controller will increasingly move towards self-optimising machines.

- Forming: Innovative vision systems are the key: Producers of trays, bottles or packaging should always question what impact material changes might have on the integrity, colour or shape of the item. Automation solutions help them to check properties. When manufacturing a container, tight temperature controls in conjunction with physical effects such as pressure are required. To avoid defective items, powerful vision systems that have the necessary tools to detect problems such as micro-holes in plastics are advisable

- Wrapping: Controlling temperature and movement: Material changes can also affect performance: Are integrity and stability still guaranteed when wrapping, for example? An application is needed that guarantees tight control of temperature and movement, maintains tension and ensures that a secondary or tertiary package is wrapped correctly.

- Handling: Ensuring seamless communication between systems: As packages get smaller, manufacturers need to find out if handling operations supported by sorting or pick-and-place solutions are accurate and easy to repeat. One example is the placement of trays into retail-ready tertiary containers. A key aspect of handling is being able to “see” the products entering the packaging area, as well as fast communication between the image processing system, the conveyor belt and the robot– all while respecting the required throughput. In addition, the configuration of the robot may need to be changed due to new film materials.

- Closing: High-resolution servos are a must: Weight reductions can change the size and shape of containers, affecting the sealing process and other related workflows. Additionally, forces and torques can lead to more waste or production downtime, which can cause further problems. Many sealing techniques such as capping rely on servo control. High-resolution servos connected via a machine network such as EtherCAT are therefore important.

- Rely on an experienced partner: Instead of tackling the battle for more sustainability alone, it is advisable to bring strong partners on board. With its integrative technology, i-Automation, as well as globally available services, OMRON supports food and beverage companies in all the challenges mentioned. International presence, a large network of integration and cooperation partners and the focus on the WHO’s sustainability goals make OMRON an experienced and competent companion on this important journey.

The urgency of addressing these environmental challenges can’t be stressed enough. By making better choices when it comes to packaging, the food industry can play a vital role in reducing waste, conserving resources as well as mitigating climate change. The adoption of sustainable packaging methods is not only the responsible thing to do, but it is also a financially sound one. Embracing eco-friendly packaging not only reduces your environmental footprint but can also boost your bottom line while ensuring a healthier planet for future generations. It’s time to embrace the packaging revolution and be part of the solution to save our planet, one package at a time.

Written for Omron OEE-ZA